Catheter manufacturers

The

PCN catheter was

originally described by urologist Dr Willard Goodwin in 1955 as a minimally

invasive, x-ray guided temporary or permanent procedural alternative to

traditional surgery in patients with hydronephrosis. Catheter manufacturers using clinical data

find four broad indications for a PCN placement, which are; first for the

relieving of urinary obstruction, second, diagnostic testing, third for access, for therapeutic interventions, and

fourth urinary diversion.

|

| PCN catheter |

Relief

from urinary obstruction is the most common cause for PCN catheter placement

representing 85 to 90% of recipients. The top three causes of renal obstruction

in adults are iatrogenic benign stricture, urinary stones, and malignancy. From

imaging, diagnoses can be made with computed tomography (CT), ultrasound,

magnetic resonance imaging (MRI), or nuclear medicine of renal obstruction.

Ultrasound is usually option one due to high sensitivity for detecting a

dilated collecting system, relative availability, and minimal risk. However, as

opposed to other methods of imaging, it is not as effective in identifying the etiologic

location of the obstruction. Non-contrast CT can effectively detect hydronephrosis

and has the added benefit of being highly sensitive for the detection of

obstructing stones in exceptionally large patients with renal impairment. For

people with normal urinary function, contrast-enhanced computed tomography has

a very high success ratio in finding the cause of hydronephrosis. Because an

uninfected obstructed kidney is not seriously threatened, as a rule, PCN catheter placement is an urgent rather than emergent process. Clinical data suggest

that complete recovery of the glomerular filtration rate (GFR) happens within a

week. Percutaneous nephrostomy is the process of inserting a small, flexible rubber tube (catheter)

through the skin into the kidney to drain urine. A

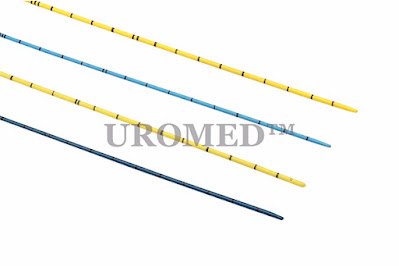

catheter is a flexible tube made of Teflon, latex, or silicone and can be

inserted into the body creating a channel, from within, for the entry of a

medical device, or passage of fluid to

the exterior. For many years, the epidermal catheters used were ordinary tubes

made of available industrial compounds, and design was largely based on current

need.

Advancements

in material technology and medical science have created new technical

challenges for medical devices applied in minimally invasive interventional

procedures. Medical apparatus companies are making devices that are more

complex, less cumbersome, less invasive, and multifunctional, which require

tighter tolerances from their contract manufacturers and greater precision. For

instance, in the extrusion business, device companies continue to develop

complex new designs for single products that require co-extrusion, variable

coil/braid reinforcements, multi durometer segments, or multi-lumen. Progressively

complex designs, tooling, materials, and prototyping all pump-up costs, yet

cost-saving needs to be designed into the final product, without compromising function

or quality. One way of achieving this is by speeding up the manufacturing

process by improving efficiencies, automation, and reducing waste. Another

means would be to partner with someone skilled in the practice of designing

for manufacturability; that is, designing products and processes that remove

certain steps, such as assembly and finishing.

A catheter can be inserted or placed into a body

cavity, duct, or vessel. Functionally, they perform a wide variety of tasks

depending on the type of catheter, they provide access by surgical instruments,

drainage, and, administration of fluids or gases. Procedurally, catheterization is the process of inserting a catheter. Made of Teflon, latex, or

silicone, catheters are thin, flexible tubes, and are available in varying

levels of rigidity depending on the purpose. A catheter reposed inside the

body either permanently or temporarily is called an indwelling catheter. There

are many different types of catheters, for many different purposes, and we will

look at the different types and functions in another article

Comments

Post a Comment